The WARP Shoe Company Project

- Category: Programming, Optimization

- Client: The University of Toronto

- Project date: April 2021

Problem Statement

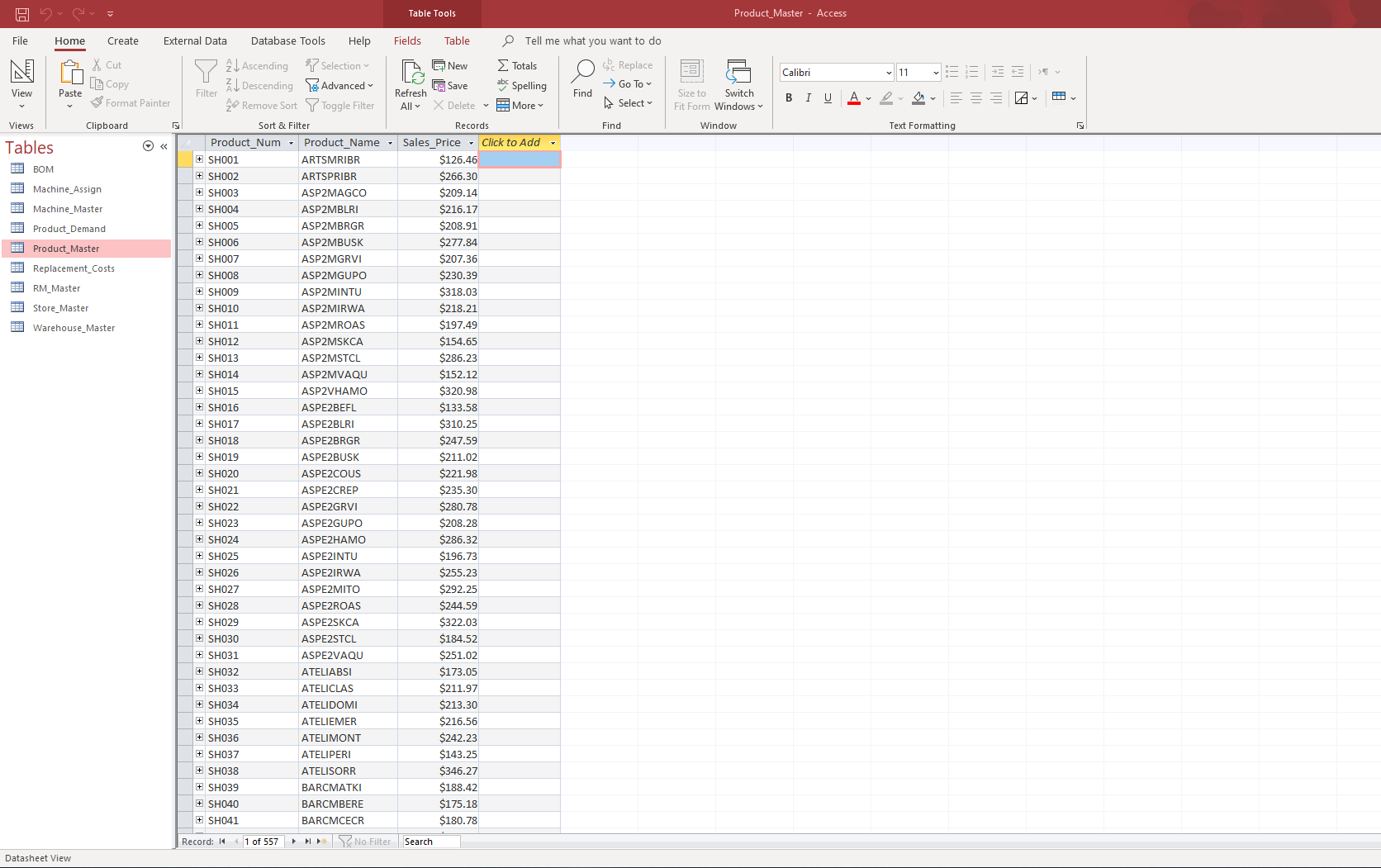

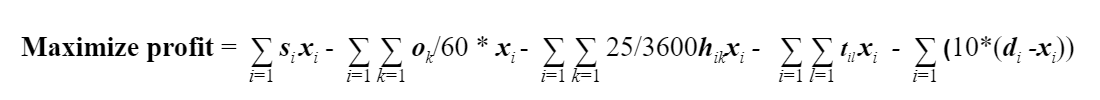

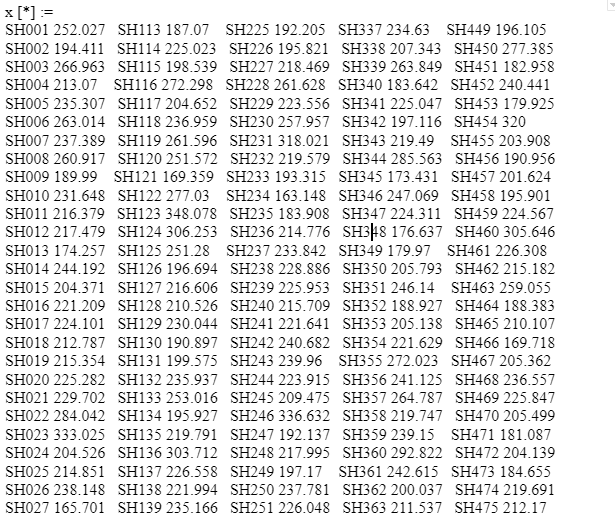

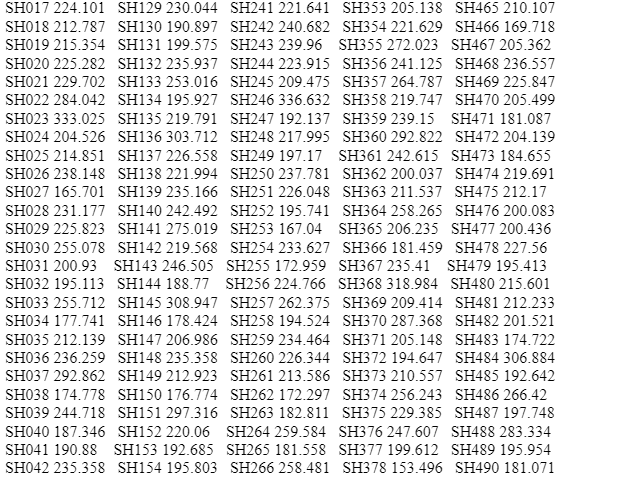

At the beginning of year 2006, one of the major market competitors of WARP went bankrupt. Thus, WARP market analysts predict that for the month of February the demand for all types of shoes will double. Assume that closing inventory of January 2006 was zero for alltypes of shoes. Assume also that all sales happen at the end of the month. The management of WARP wants to know what is the most profitable production plan. This project is aimed at determining the optimal production strategy to achieve maximum profit for the WARP Shoe Company.